isifinyezo

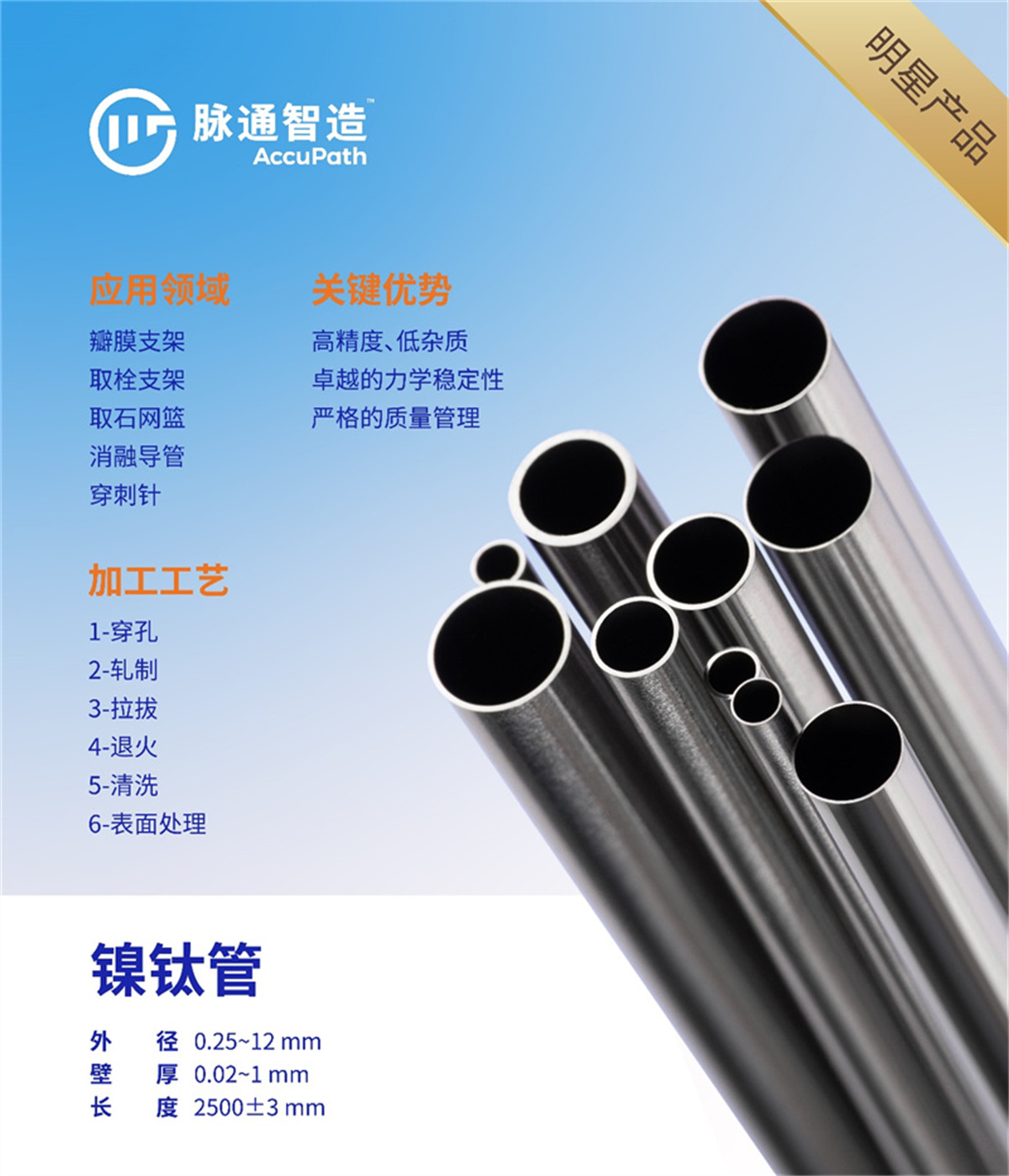

Amashubhu e-nickel-titanium asetshenziswa kakhulu emishinini yokwelapha yokungenelela, futhi i-superelasticity yabo kanye nezakhiwo zememori yokuma kulethe inqubekelaphambili yenguquko emkhakheni wemishini yezokwelapha. I-Maitong Intelligent Manufacturing™Ngobuchwepheshe obusezingeni eliphezulu kanye nokulawulwa kwekhwalithi okuqinile, amashubhu e-nickel-titanium asezingeni eliphakeme akhiqizwa, angafinyeleli kuphela emazingeni ahamba phambili embonini ngokunemba kobukhulu kanye nokuzinza kokusebenza, kodwa futhi abonise imiphumela evelele ekuhlanzekeni kanye nobuchwepheshe bokwelapha obungaphezulu. Le mikhiqizo emisha kanye nezinsizakalo ezenziwe ngokwezifiso ngokungangabazeki zizothuthukisa izixazululo zokwelapha eziphephile embonini yemishini yezokwelapha.

Ubuchwepheshe be-Cutting-Edge obuhlanganiswe nobuciko obuhle

Enqubweni yokukhiqiza amapayipi e-nickel-titanium, i-Maitong Intelligent Manufacturing™ ikhetha inqubo efanele yokubumba ngokubamba imithetho eguqukayo yokugeleza kwensimbi phakathi kwamazinga ahlukene okuguga okusebenzayo okubandayo, izifunda ezihlukene zokuhlanganisa kanye nezindlela ezahlukene zokucubungula ukuze kuqinisekiswe ukuthi azikho izingxenye zasendaweni ezenzeka ngesikhathi inqubo yokugeleza kwepayipi, futhi ulawule ukunemba kobukhulu kwamapayipi engxubevange ye-nickel-titanium kusukela emininingwaneni efana nobudlelwane bokuqina, izinga lokuqina komsebenzi, izinga lokunwetshwa kodonga, njll. Ekulungiseni amaphutha nasekulawuleni ukusebenza, i-Maitong Intelligent Manufacturing™ yenza ucwaningo olunzulu mayelana nokuziphatha kokuziphendukela kwemvelo kwenhlangano phakathi nenqubo yokuhlanganisa, iphethe indlela yokuqinisa neqinisayo yama-alloys e-nickel-titanium, ithuthukisa ngokwengeziwe izakhiwo zemishini, futhi ifinyelela amandla-plasticity afanele. ukufanisa ukuhlangabezana nezidingo zemishini yezokwelapha ehlukahlukene.

Ukuphathwa kwekhwalithi okuqinile ukuze udale amabhentshimakhi ekhwalithi yomkhakha

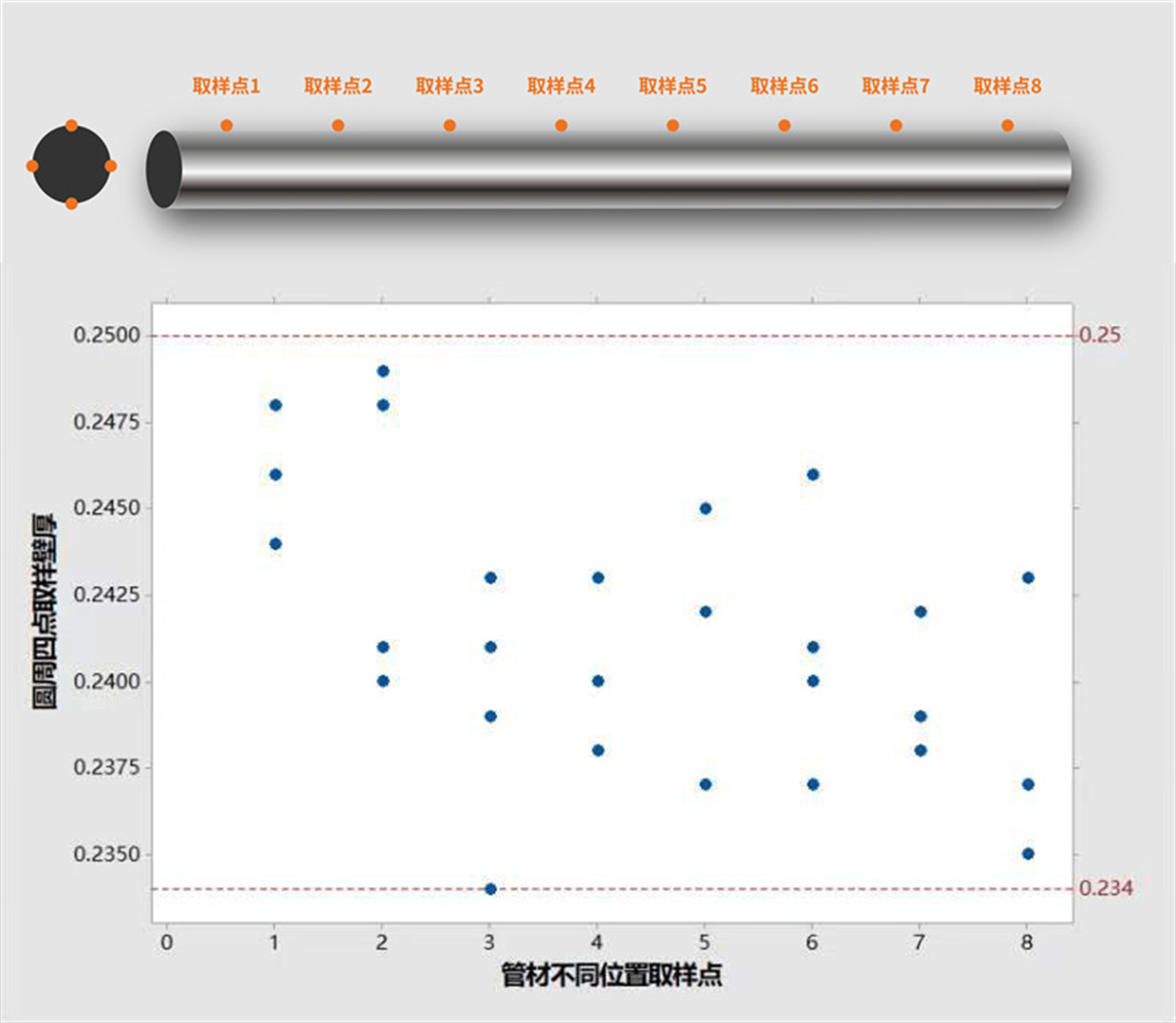

I-Maitong Intelligent Manufacturing™Ukukhiqizwa kwamashubhu e-nickel-titanium kuhilela uchungechunge lwezinyathelo eziqondile, kusukela ekulungiselelweni okungenalutho kweshubhu kuya ekuhlolweni kwekhwalithi yokugcina. Isinyathelo ngasinye sokubhoboza, ukugingqika, ukudweba, ukuthungatha, ukuhlanza kanye nokwelashwa kwendawo kuhambisana nokuhlolwa kwekhwalithi okuqinile ukuze kuqinisekiswe ukulawulwa okunembile kokwakheka kwengxubevange kanye nokunciphisa ukungcola, ngaleyo ndlela kuqinisekiswe ukuhlanzeka kwamakhemikhali kanye nezakhiwo ezincane zomkhiqizo.

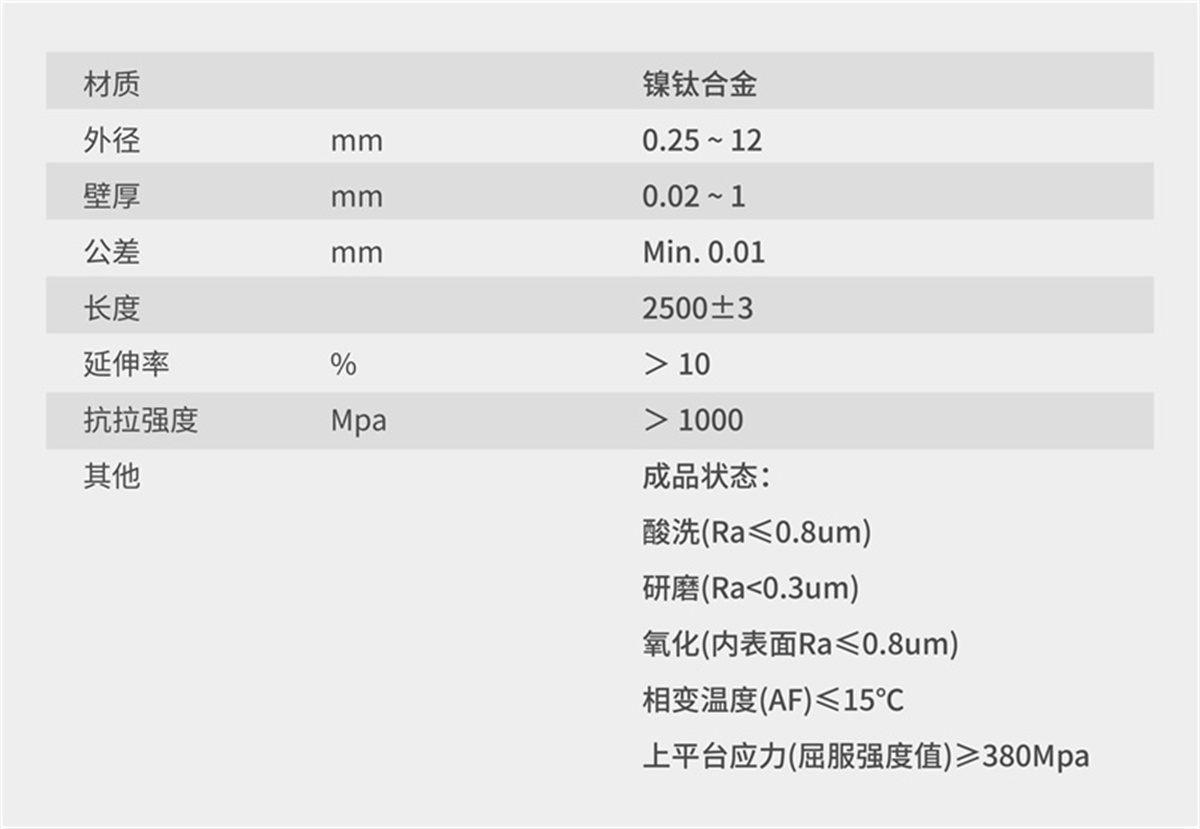

Inkampani iqondisa ngokuqinile imikhiqizo kusukela ekuthathweni kwesidingo kuye kokubuyekezwa, ukukhiqizwa, ukuhlolwa, nokulethwa ukuze kuqinisekiswe ikhwalithi yomkhiqizo. Ngaphezu kwalokho, ukugcinwa kwesampula ngesikhathi senqubo yokukhiqiza kuqinisekisa ukulandeleka komkhiqizo, ukubeka isisekelo esiqinile sokulandelelwa kwekhwalithi kanye nokwenza ngcono okuqhubekayo. Idatha yokuhlola efanelekile ibonisa:

Ukuphathwa kwekhwalithi okuqinile ukuze udale amabhentshimakhi ekhwalithi yomkhakha

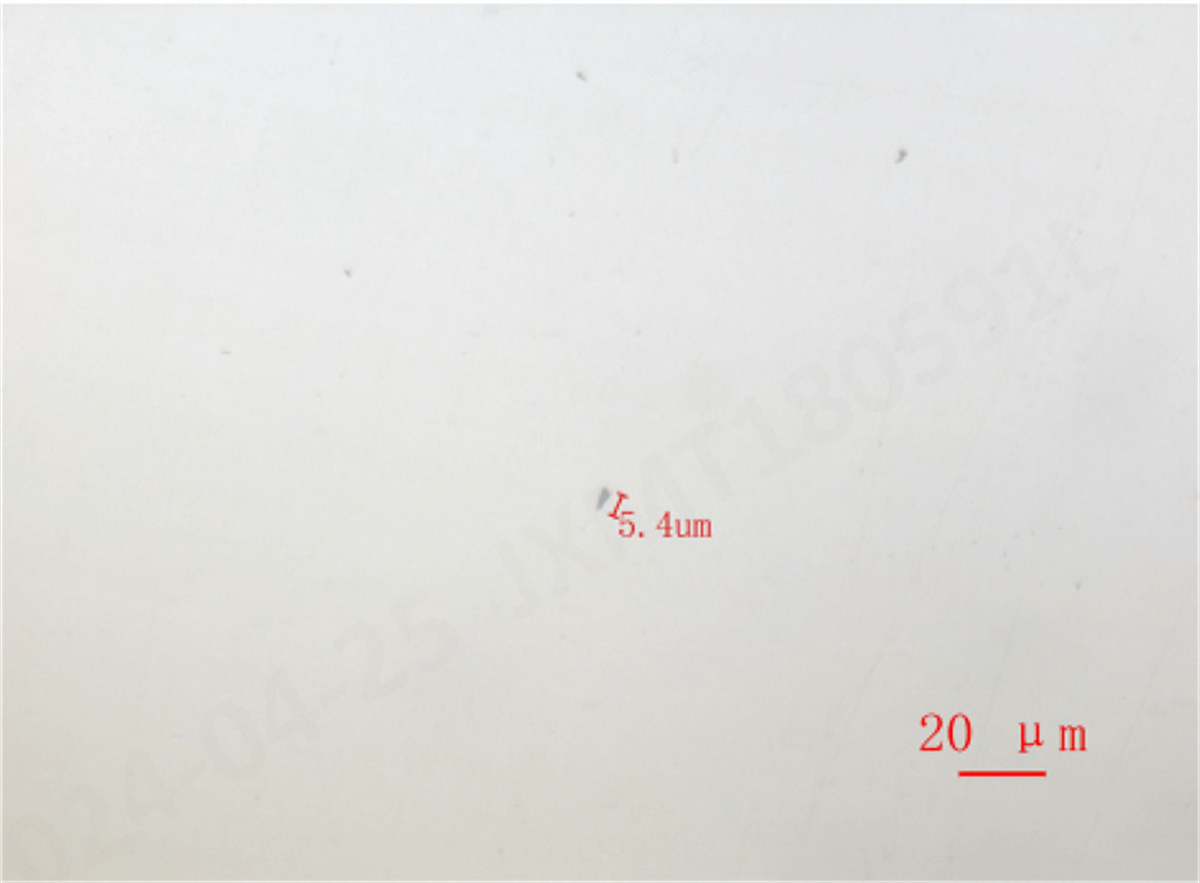

Ubukhulu obuncane bezinhlayiya zokufakwa okuxekethile nezingezona ezensimbi ku-microstructure yezinto ezingavuthiwe zilawulwa kahle ngaphakathi kwe-5.4 μm, futhi isilinganiso sendawo esiphezulu singu-0.5% kuphela, kuqinisekisa ukumelana nokukhathala okungcono.

Ukufakwa kwesampula okungu-500x

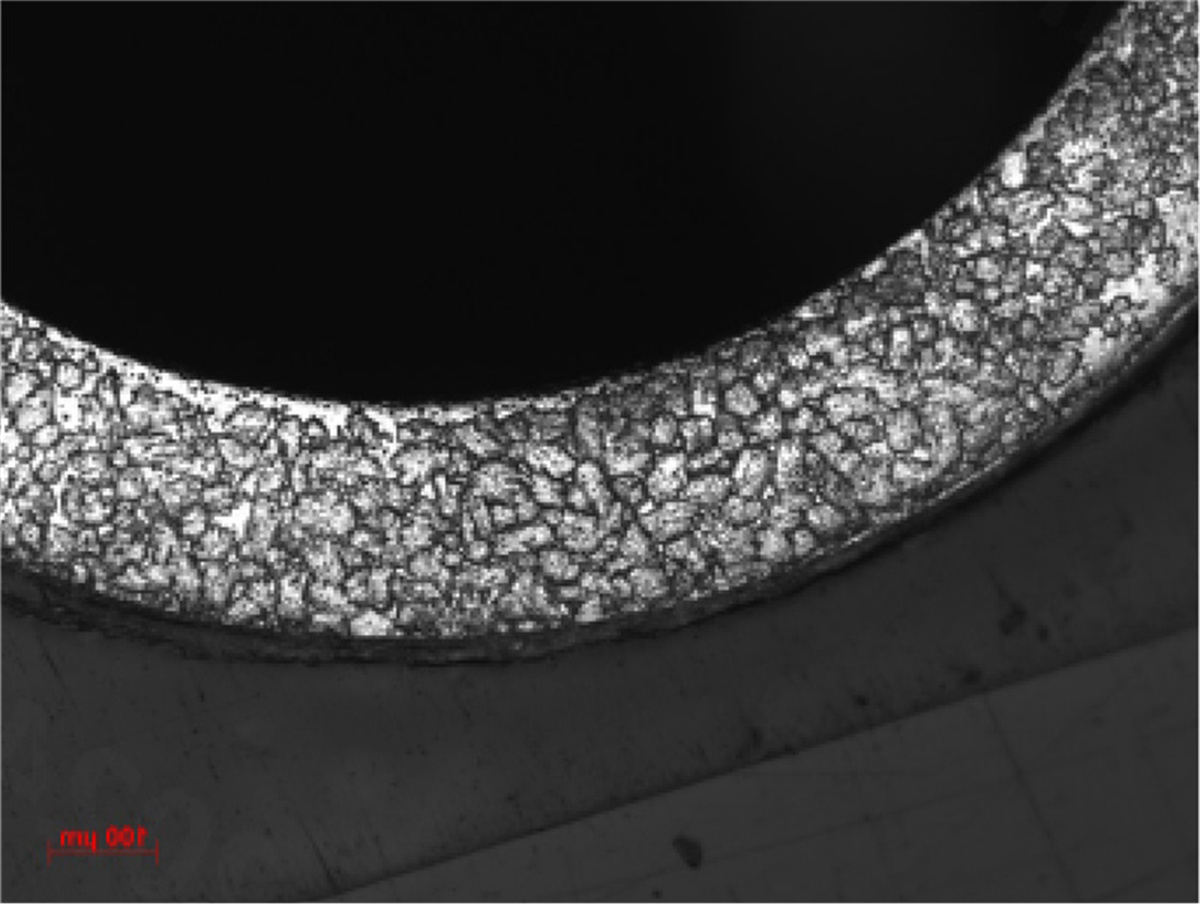

I-Microstructure yepayipi eqediwe

Usayizi wokusanhlamvu wepayipi eliqediwe lifinyelela ezingeni lesi-7, futhi akukho ama-pores acacile kanye nokufaka okutholakalayo I-porosity kanye nokuqukethwe okungenayo insimbi okungenayo kuphansi kakhulu, ngephesenti yendawo kuphela ye-0.2%, iqinisekisa ukumelana nokukhathala okungcono.

Usayizi wokusanhlamvu wesampula

Ukufakwa kwesampula 200x 500x

Ukuzinza okuhle kakhulu kwemishini

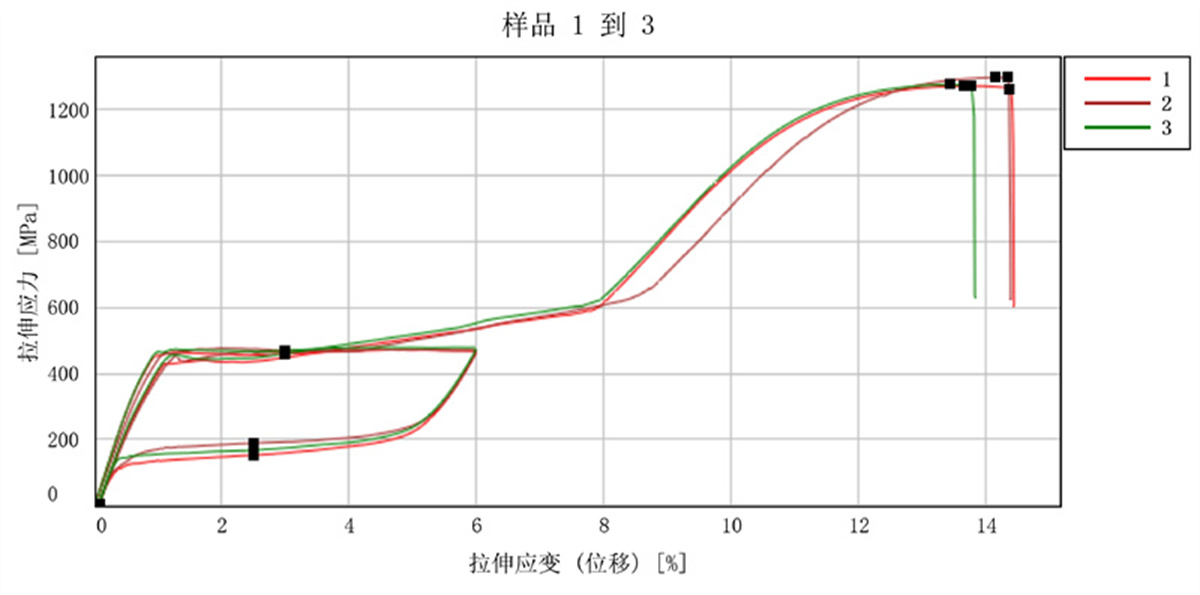

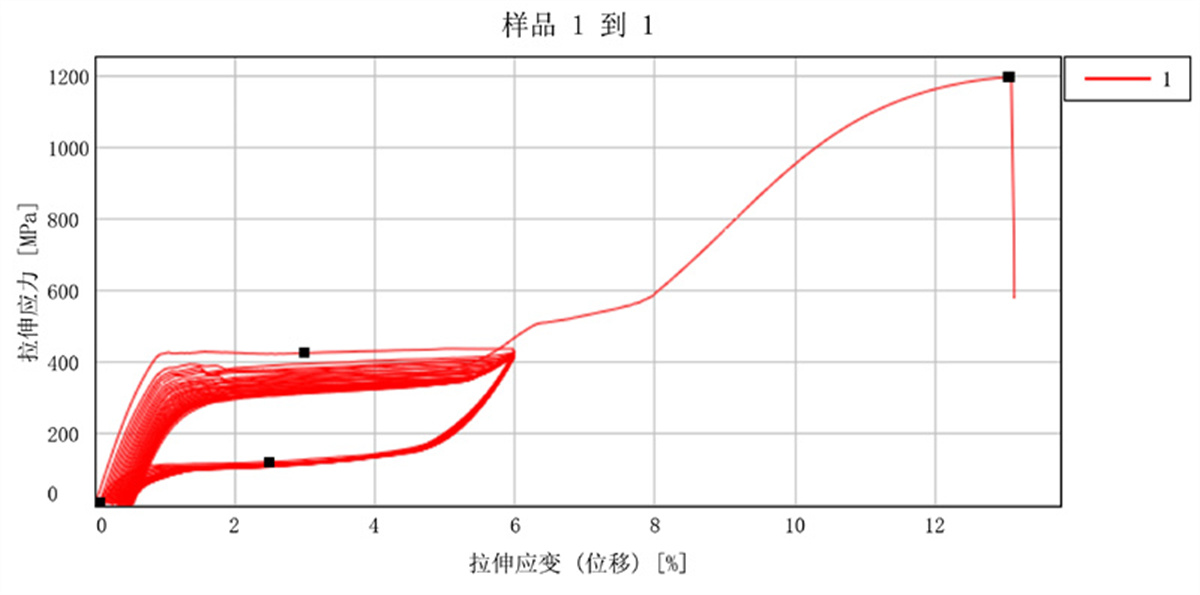

Ngemuva kokwelashwa okucophelela kwe-thermomechanical kanye nokulawulwa okunembile kwezinga lokushisa kwesigaba, isampula libonise ukuzinza okuhle kakhulu komshini ngemva kokuhlolwa okungu-20 kwemijikelezo yokutakula ukuguquguquka okungu-6%. Ngaphezu kwalokho, umkhiqizo unokuvumelana nezimo okuhle kakhulu futhi ungalungisa ukusebenza kwawo ngokuvumelana nezidingo zamakhasimende.

Ngaphezu kwalokho, i-Maitong Intelligent Manufacturing™ inemishini nezindlela zokuhlola eziphelele, ezingakwazi ukuhlola ukusebenza okuqinile okuqinile, ukuhlaziya ukunwetshwa kokushisa okushisayo, ukuzimisela kwesici senkumbulo, ukukhula kokuphazamiseka kokukhathala kanye nokuhlolwa kokuziphatha kokuqina kwemikhiqizo.

Ukunemba okuphezulu, ukungcola okuphansi” ultra-pure nickel-titanium tube

Ngohlelo lokuphatha lwekhwalithi ephezulu, i-Maitong Intelligent Manufacturing™ ithuthukise uchungechunge lwemikhiqizo yamashubhu e-nickel-titanium ehlanzekile “enokunemba okuphezulu nokungcola okuphansi”. Ngokufakwa kwesici sokuhlola, ubukhulu bosayizi wokungcola ngaphakathi komkhiqizo ngu-≤12.0μm, futhi isilinganiso sendawo singu-≤0.5%.

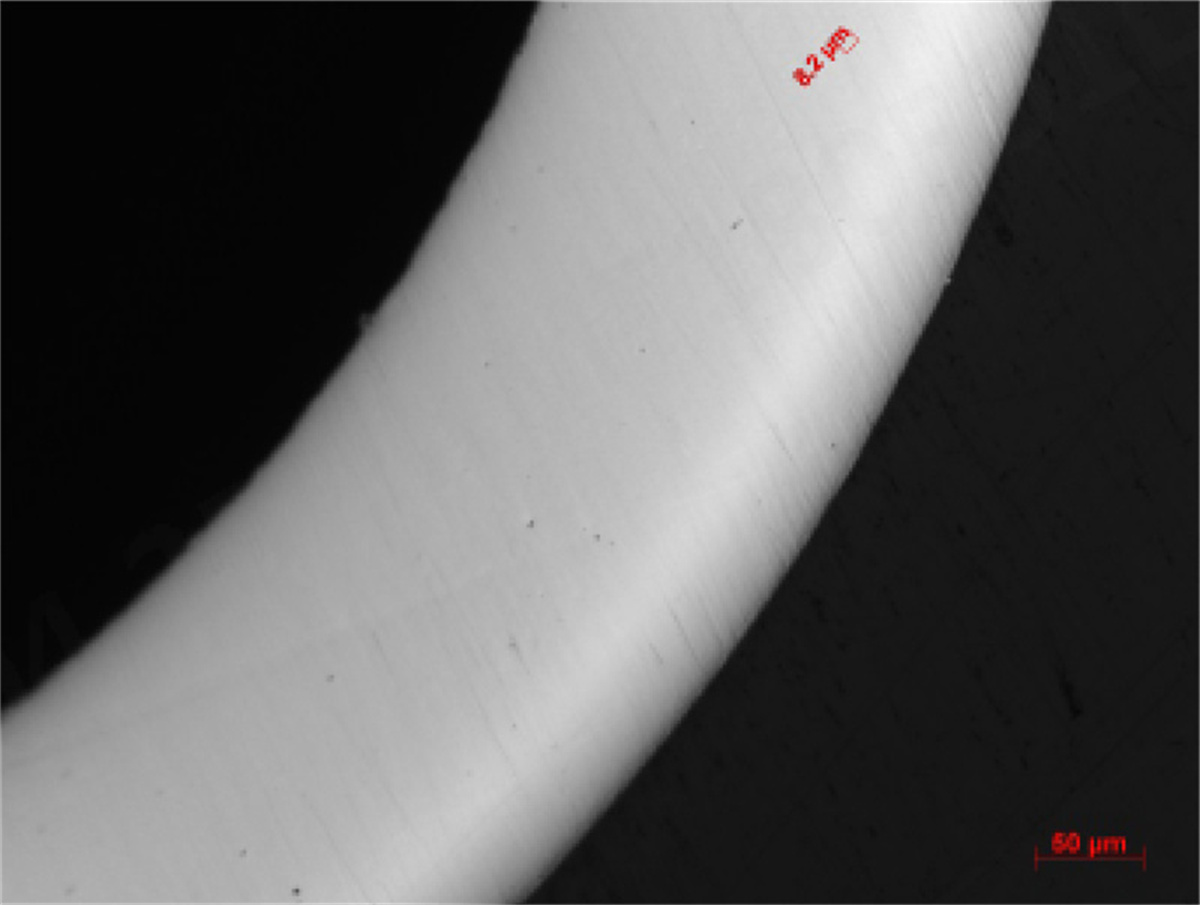

Ngaso leso sikhathi, ngosizo lochungechunge lobuchwepheshe bokuguqula indawo enembayo ephezulu njengokugaya kazibuthe kanye nokugaya okungenamaphakathi, ubulukhuni (ra) be-Maitong Intelligent Manufacturing™ nickel-titanium tubes bufinyelela ku-≤0.1μm, buthuthukise ngempumelelo ukumelana nokugqwala kwayo. kanye ne-biocompatibility.

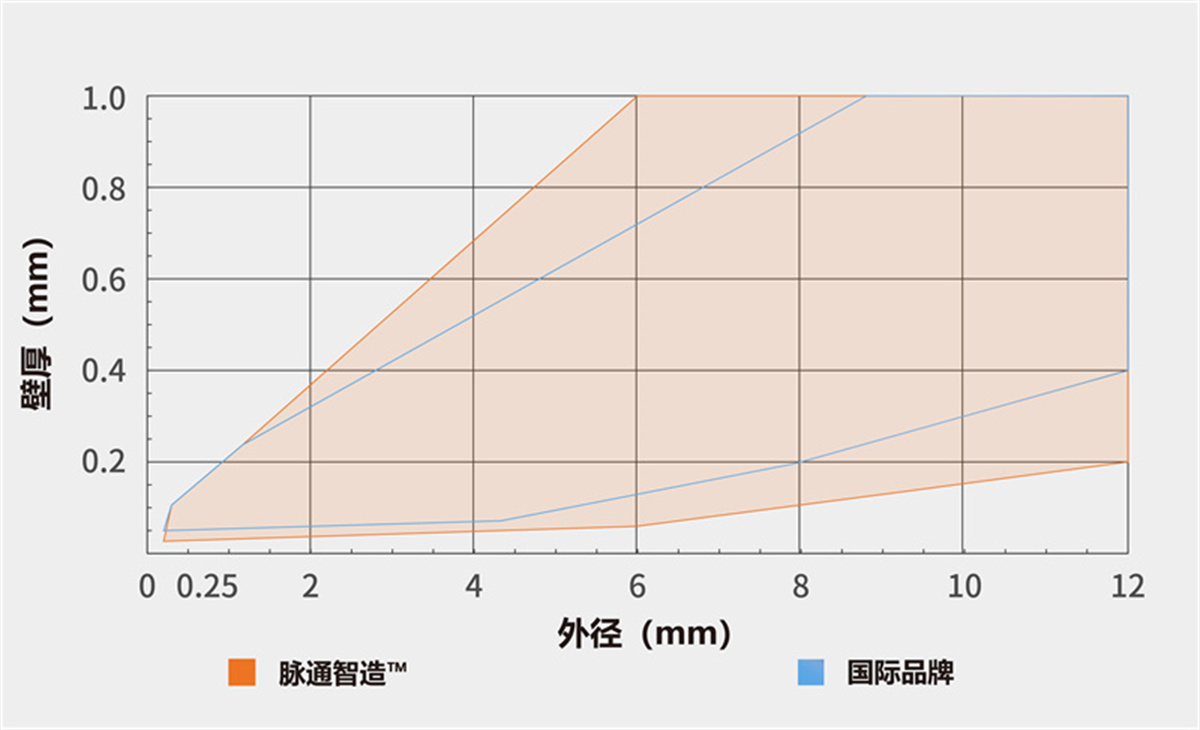

Osayizi abatholakalayo

Ngohlelo lokuphatha lwekhwalithi ephezulu, i-Maitong Intelligent Manufacturing™ ithuthukise uchungechunge lwemikhiqizo yamashubhu e-nickel-titanium ehlanzekile “enokunemba okuphezulu nokungcola okuphansi”. Ngokufakwa kwesici sokuhlola, ubukhulu bosayizi wokungcola ngaphakathi komkhiqizo ngu-≤12.0μm, futhi isilinganiso sendawo singu-≤0.5%.

Ngaphezu kwalokho, i-Maitong Intelligent Manufacturing™ ingaphinde ihlinzeke ngezinsiza ezenziwe ngokwezifiso zokucubungula ingxenye ye-nickel-titanium ngokwezidingo zamakhasimende, okuhlanganisa: ukusika i-laser, ukusetha ukushisa, ukupholisha ingxenye ye-nickel-titanium, njll.

- I-Laser Welding:Ubuncane bendawo ububanzi bungakwazi ukufinyelela ku-0.003”

- Ukusika i-Laser:Ububanzi obuncane bokusika bungu-0.001” futhi ukuphindaphinda okuphezulu ngu-±0.0001”

- Ukupholisha nge-Electrochemical:Ukuqina (ra) ≤0.1μm

Isikhathi sokukhishwa: 24-05-29