kakaretso

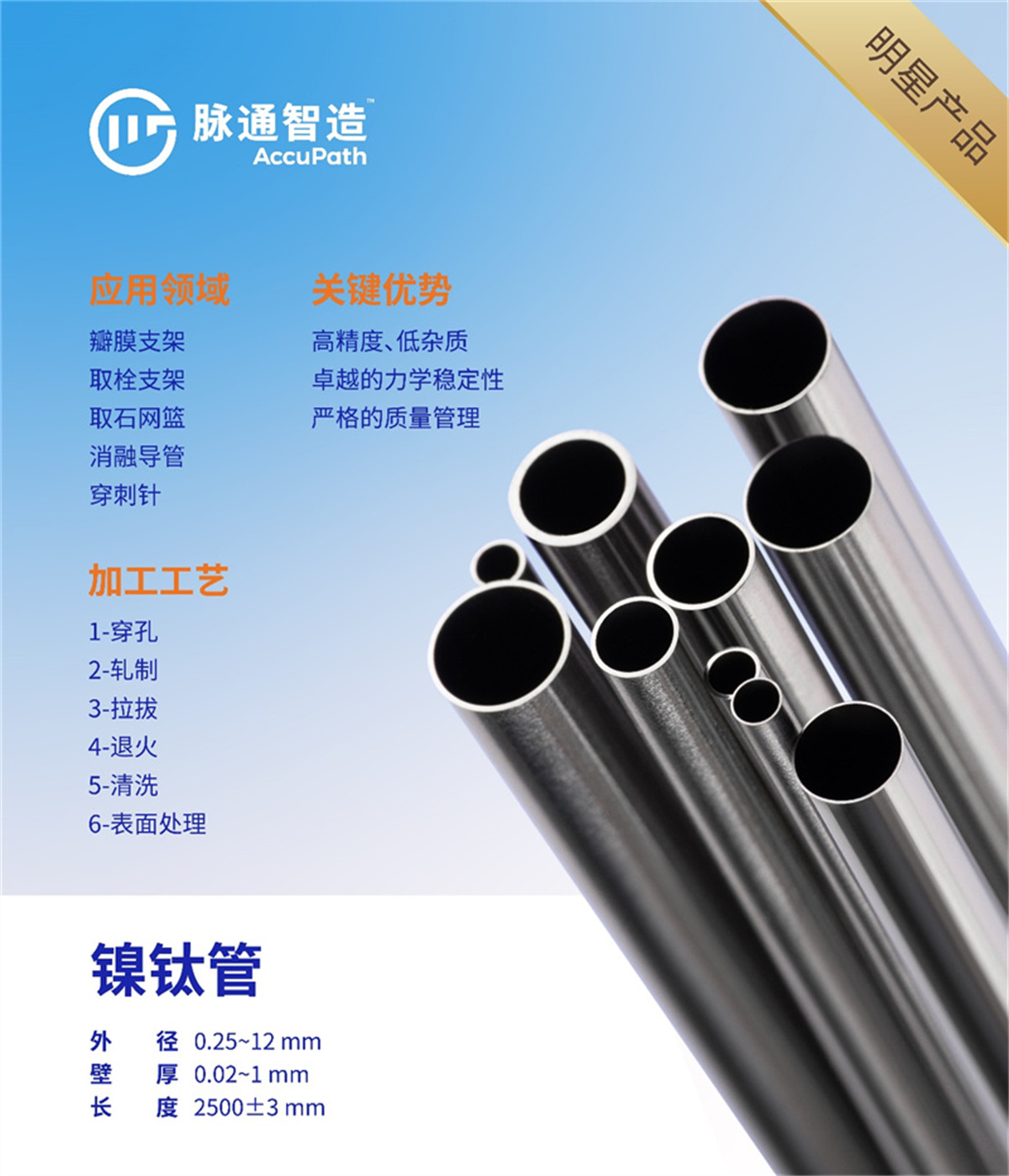

Li-tubes tsa nickel-titanium li ntse li sebelisoa ka ho eketsehileng lisebelisoa tsa phekolo ea meriana, 'me boleng ba bona ba superelasticity le sebopeho sa memori li tlisitse tsoelo-pele ea phetoho lefapheng la lisebelisoa tsa bongaka. Maitong Intelligent Manufacturing™Ka theknoloji ea morao-rao le taolo e thata ea boleng, ho hlahisoa li-tubes tsa nickel-titanium tsa maemo a holimo, tse sa fihleng feela maemong a etelletseng pele indastering ka ho nepahala ha maemo le botsitso ba ts'ebetso, empa hape li bonts'a litholoana tse ikhethang tsa bohloeki le thekenoloji ea kalafo ea holim'a metsi. Lihlahisoa tsena tse ncha le lits'ebeletso tse ikhethileng li tla khothaletsa litharollo tse sireletsehileng tsa kalafo indastering ea lisebelisoa tsa bongaka.

Theknoloji ea morao-rao e kopantsoeng le boqapi bo botle

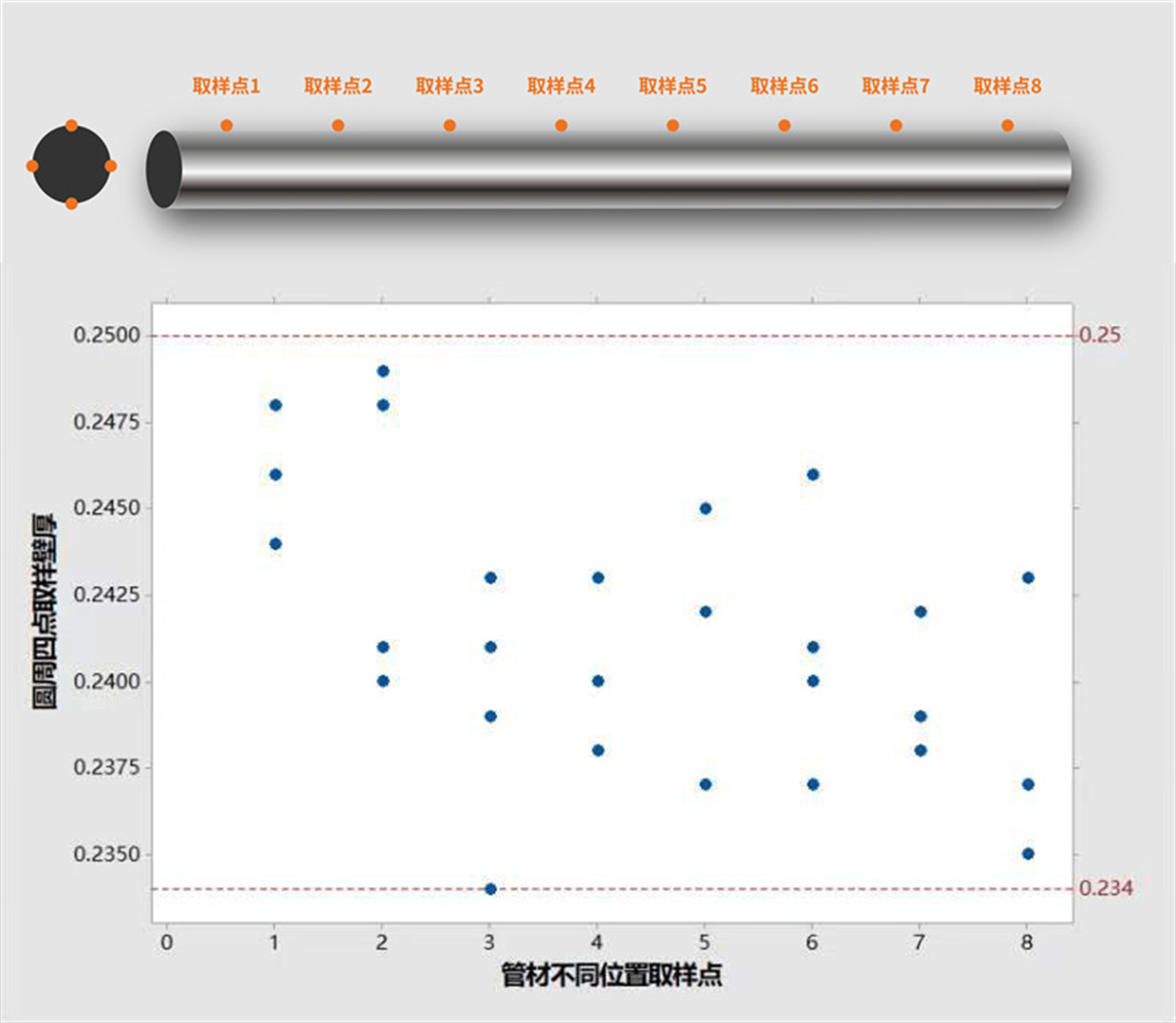

Ts'ebetsong ea tlhahiso ea liphaephe tsa nickel-titanium, Maitong Intelligent Manufacturing™ e khetha mokhoa o nepahetseng oa ho bōpa ka ho utloisisa melao e fetohang ea ho phalla ha tšepe pakeng tsa litekanyetso tse fapaneng tse fapaneng tsa ho sebetsa ha serame, libaka tse fapaneng tsa annealing le mekhoa e fapaneng ea ts'ebetso ho netefatsa hore ha ho na likarolo tse ling tse hlahang sebakeng sa heno. Ts'ebetso ea phallo ea liphaephe, le ho laola ho nepahala ha liphaephe tsa nickel-titanium alloy ho tsoa ho lintlha tse kang kamano ea matla-thata, sekhahla sa ho thatafala ha mosebetsi, sekhahla sa katoloso ea botenya ba lebota, jj. Ts'ebetsong le taolong ea ts'ebetso, Maitong Intelligent Manufacturing™ e etsa lipatlisiso tse tebileng mabapi le boits'oaro ba ts'ebetso ea mokhatlo nakong ea ts'ebetso ea ho koala, e tseba mokhoa o matlafatsang le o thata oa li-alloys tsa nickel-titanium, e ntlafatsa le ho ntlafatsa thepa ea mochini, le ho fihlela matla a nepahetseng a polasetiki. ho tsamaisana le litlhoko tsa lisebelisoa tse fapaneng tsa kopo.

Tsamaiso ea boleng bo thata ho theha litekanyetso tsa boleng ba indasteri

Maitong Intelligent Manufacturing™Tlhahiso ea li-tubes tsa nickel-titanium e kenyelletsa letoto la mehato e nepahetseng, ho tloha ho tokiso e se nang letho ho isa tlhahlobong ea boleng ba ho qetela. Mohato o mong le o mong oa ho phunya, ho phutha, ho hula, ho hloekisa, ho hloekisa le ho phekola holim'a metsi ho tsamaisana le tlhahlobo e tiileng ea boleng ho netefatsa taolo e nepahetseng ea motsoako oa motsoako le ho fokotsa litšila, kahoo ho netefatsa bohloeki ba lik'hemik'hale le thepa ea microstructural ea sehlahisoa.

Khamphani e okametse lihlahisoa ka thata ho tloha ha ho nkuoa tlhokahalo ho ea ho tlhahlobo, tlhahiso, tlhahlobo le phano ho netefatsa boleng ba sehlahisoa. Ntle le moo, ho boloka sampole nakong ea ts'ebetso ea tlhahiso ho netefatsa ts'ebetso ea sehlahisoa, ho rala motheo o tiileng oa ho lateloa ha boleng le ntlafatso e tsoelang pele. Lintlha tsa tlhahlobo tse amehang li bontša:

Tsamaiso ea boleng bo thata ho theha litekanyetso tsa boleng ba indasteri

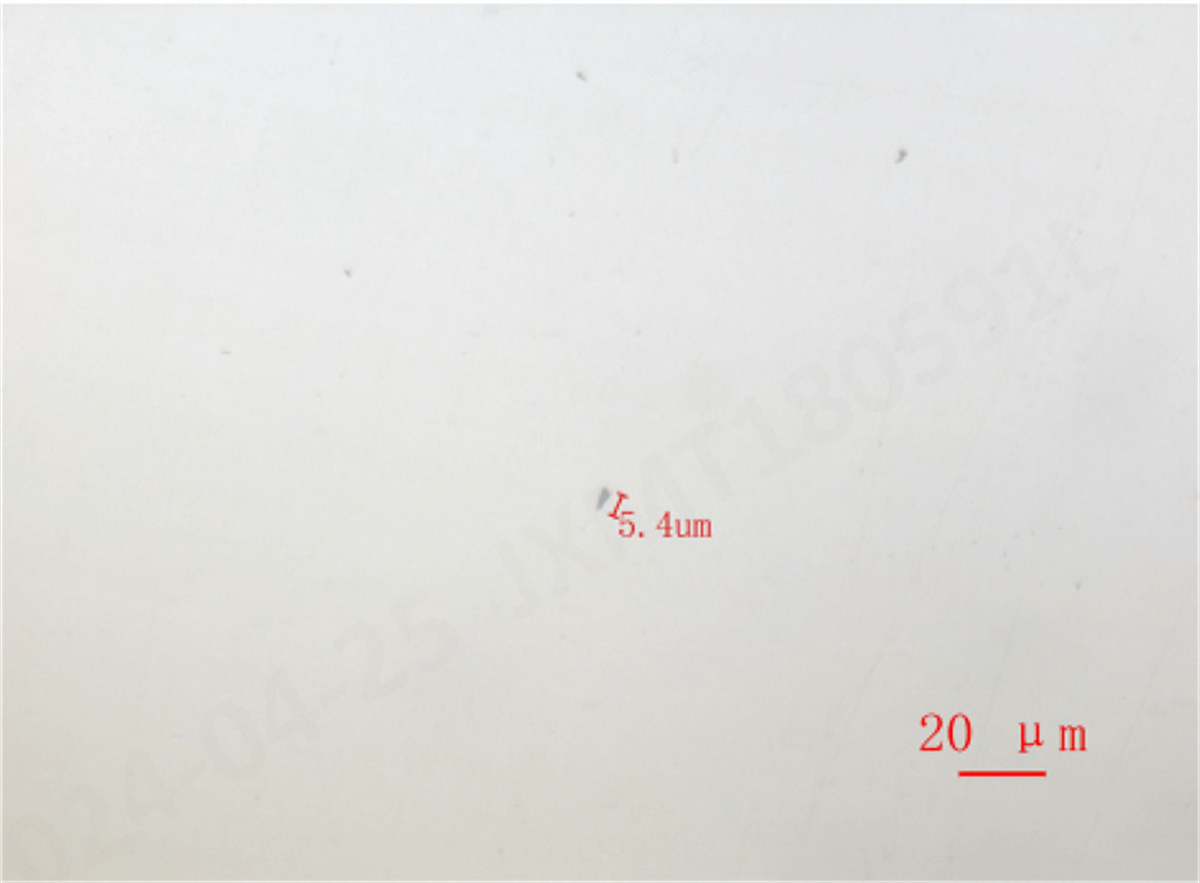

Boholo bo fokolang ba likaroloana tse hlephileng le tse se nang tšepe tse kenyelletsoeng ka har'a microstructure ea lihlahisoa tse tala li laoloa ka mokhoa o nepahetseng ka har'a 5.4 μm, 'me sebaka se seholo sa sebaka ke 0.5% feela, ho tiisa hore ho hanyetsa mokhathala ho molemo.

Mohlala oa ho kenyelletsa 500x

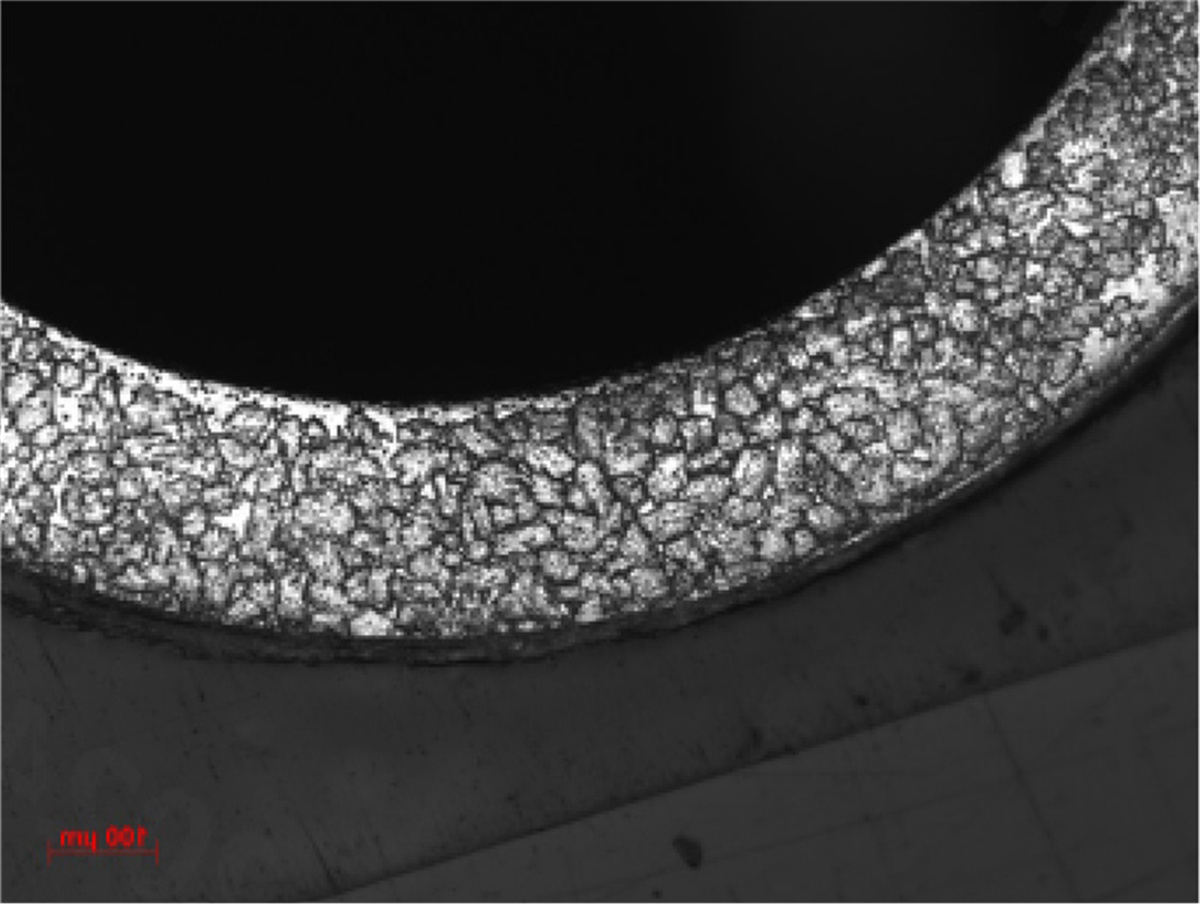

Microstructure ea phala e phethiloeng

Boholo ba lijo-thollo tsa phala e phethiloeng bo fihla boemong ba 7, 'me ha ho na li-pores le li-inclusions tse hlakileng tse fumanoang porosity le lintho tse se nang tšepe tse kenyelletsoeng li fokotsehile haholo, ka karolo ea sebaka sa 0,2% feela, ho netefatsa hore ho hanyetsa mokhathala ho molemo.

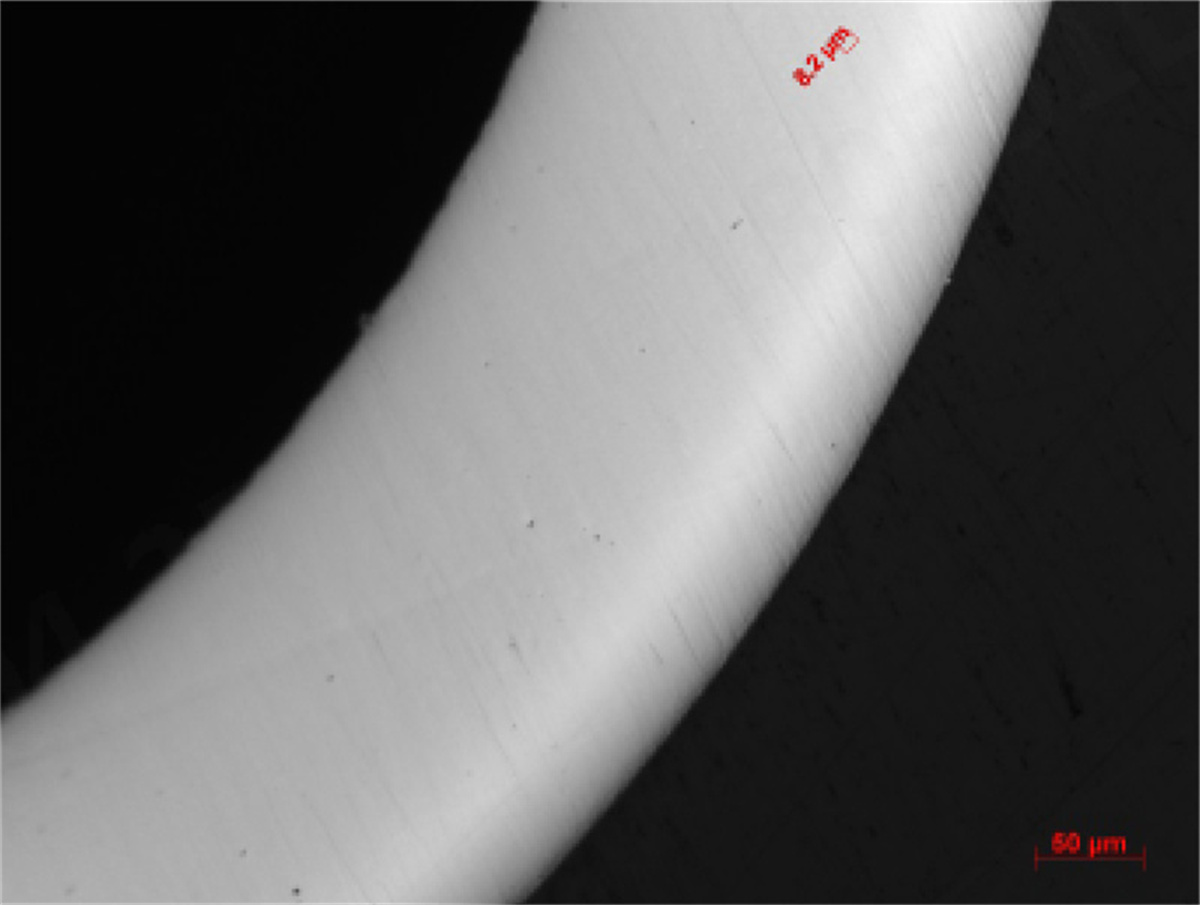

Boholo ba lijo-thollo tsa sampole

Mohlala oa ho kenyelletsa 200x 500x

E babatsehang botsitso ba mechine

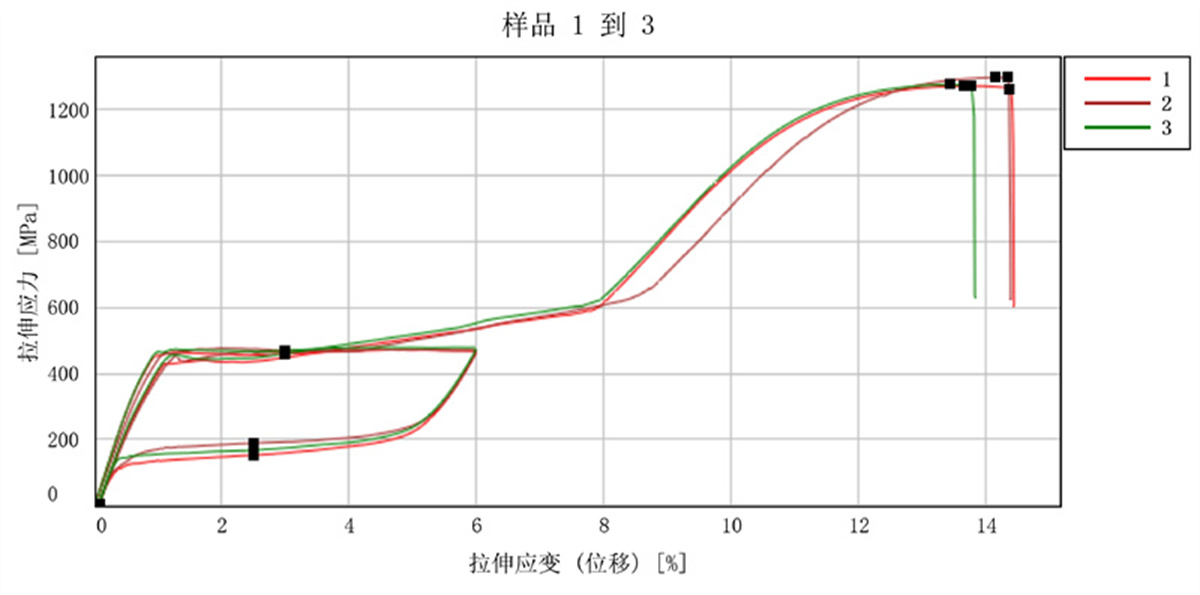

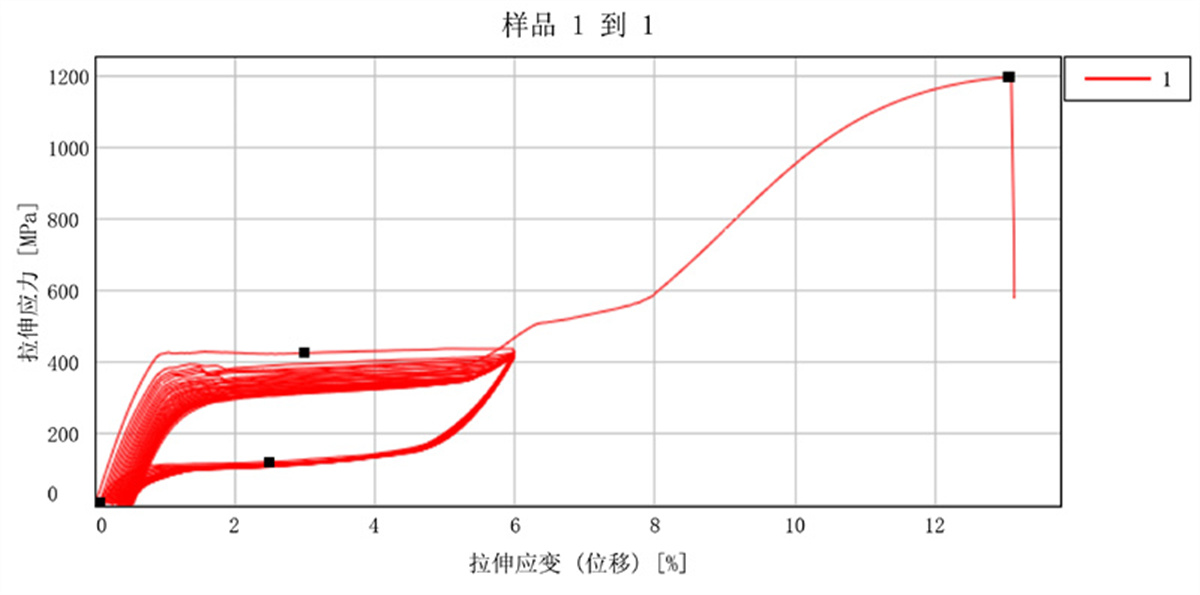

Kamora kalafo e hlokolosi ea thermomechanical le taolo e nepahetseng ea phetoho ea mocheso, sampole e bonts'itse botsitso bo botle ka mor'a liteko tse 20 tsa 6% ea potoloho ea ho hlaphoheloa ha deformation. Ho phaella moo, sehlahisoa se na le mekhoa e metle ea ho ikamahanya le maemo 'me se ka fetola tshebetso ea sona ho latela litlhoko tsa bareki.

Ntle le moo, Maitong Intelligent Manufacturing™ e na le lisebelisoa tse felletseng tsa tlhahlobo le mekhoa, e ka etsang tlhahlobo e felletseng ea ts'ebetso, tlhahlobo ea katoloso ea mocheso, boikemisetso ba sebopeho sa mohopolo, kholo ea mokhathala le tlhahlobo ea boits'oaro ba lihlahisoa.

E phahameng ka ho fetesisa, e sa hloekang ka tlase” tube ea nickel-titanium e hloekileng haholo

Ka sistimi ea maemo a holimo ea taolo ea boleng, Maitong Intelligent Manufacturing™ e hlahisitse letoto la lihlahisoa tsa "ultra-pure nickel-titanium tube" tse nang le "ho nepahala ho phahameng le litšila tse tlase". Ka tlhahlobo ea tlhahlobo, boholo ba ho se hloeke ka har'a sehlahisoa ke ≤12.0μm, 'me karo-karolelano ea sebaka ke ≤0.5%.

Ka nako e ts'oanang, ka thuso ea letoto la litheknoloji tsa ho fetola bokaholimo ba maemo a holimo joalo ka ho sila ka matla a khoheli le ho sila ho se nang setsi, bokhopo (ra) ba Maitong Intelligent Manufacturing™ nickel-titanium tubes bo fihla ho ≤0.1μm, ka katleho ho ntlafatsa ho hanyetsa ho bola ha eona. le biocompatibility.

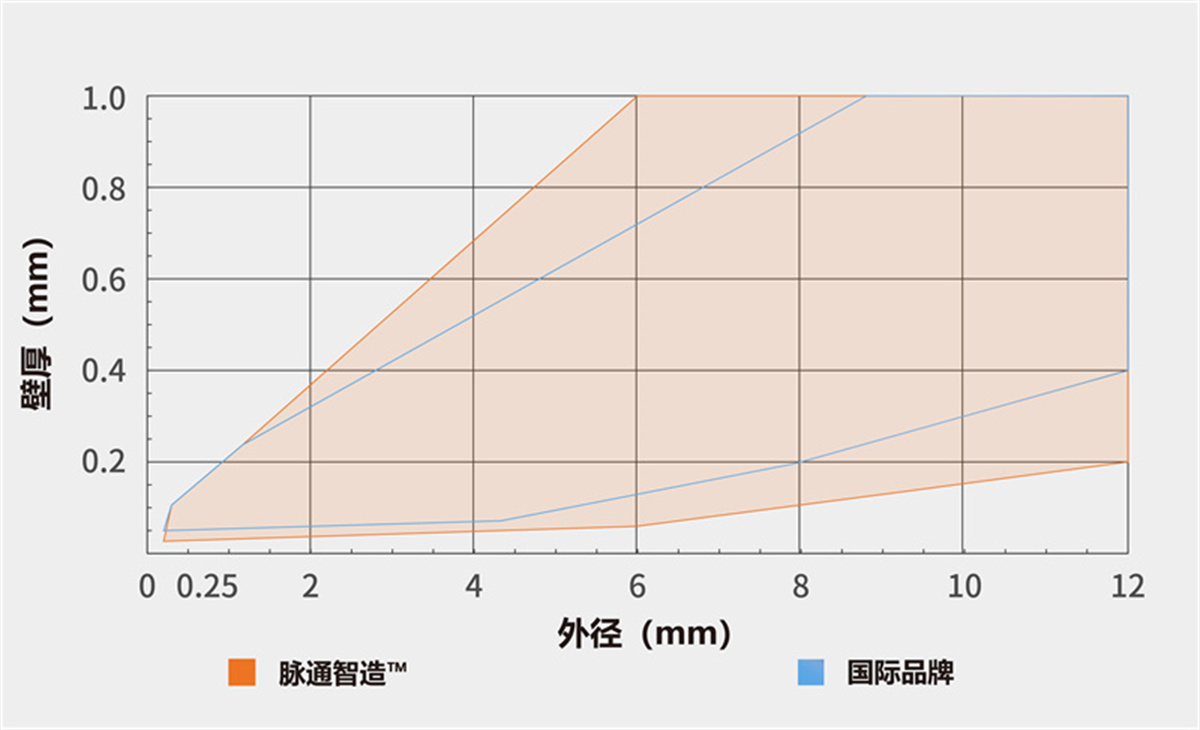

Boholo bo fumanehang

Ka sistimi ea maemo a holimo ea taolo ea boleng, Maitong Intelligent Manufacturing™ e hlahisitse letoto la lihlahisoa tsa "ultra-pure nickel-titanium tube" tse nang le "ho nepahala ho phahameng le litšila tse tlase". Ka tlhahlobo ea tlhahlobo, boholo ba ho se hloeke ka har'a sehlahisoa ke ≤12.0μm, 'me karo-karolelano ea sebaka ke ≤0.5%.

Ntle le moo, Maitong Intelligent Manufacturing™ e ka fana ka lits'ebeletso tsa ts'ebetso ea likarolo tsa nickel-titanium ho latela litlhoko tsa bareki, ho kenyelletsa: ho itšeha ka laser, ho beha mocheso, polishing ea nickel-titanium, joalo-joalo.

- Laser welding:Bophahamo bo fokolang ba sebaka bo ka fihla ho 0.003"

- Ho itšeha ka laser:Bophara bo fokolang ba ho seha ke 0.001" 'me ho pheta-pheta ho fetisisa ke ± 0.0001"

- Electrochemical polishing:Mathata (ra) ≤0.1μm

Nako ea ho lokolloa: 24-05-29