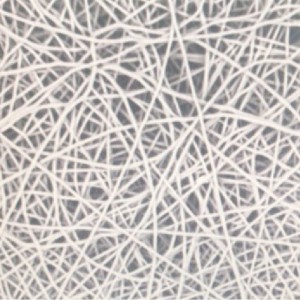

Filimi e bataletseng

Letoto le fapaneng

Botenya bo nepahetseng, matla a phahameng haholo

Sebaka se boreledi

osmosis e tlase ea mali

Biocompatibility e ntle haholo

Flat laminates ka sebelisoa ka mefuta e fapaneng ya disebediswa tsa bongaka, ho akarelletsa le

● Setente se koahetsoeng

● Sefuba sa pelo le methapo ea mali

● Cerebral vascular thrombosis barrier membrane

| unit | Reference value | |

| 404085- Lintlha tsa theknoloji | ||

| botenya | mm | 0.065~0.085 |

| boholo | mm*mm | 100xL100150×L300150×L240 240×L180 240×L200 200×L180 180×L150 200×L200 200×L300(FY) 150×L300(FY) |

| ho kena metsing | ml/cm2.min) | ≤300 |

| warp tensile strength | newton/mm | ≥6 |

| Weft tensile matla | newton/mm | ≥ 5.5 |

| Matla a phatlohang | N | ≥ 250 |

| Matla a suture a hula (5-0PET suture) | N | ≥1 |

| 404070- Lintlha tsa theknoloji | ||

| botenya | mm | 0.060~0.070 |

| boholo | mm*mm | 100×L100150×L200180×L150 200×L180 200×L200 240×L180 240×L220 150×L300 150×L300(FY) |

| ho kena metsing | ml/(cm2/min) | ≤300 |

| warp tensile strength | newton/mm | ≥6 |

| Weft tensile matla | newton/mm | ≥ 5.5 |

| Matla a phatlohang | N | ≥ 250 |

| Matla a suture a hula (5-0PET suture) | N | ≥1 |

| 402055- Lintlha tsa theknoloji | ||

| botenya | mm | 0.040-0.055 |

| boholo | mm*mm | 150xL150200×L200 |

| ho kena metsing | ml/(cm².motsotso) | <500 |

| warp tensile strength | newton/mm | ≥6 |

| Weft tensile matla | newton/mm | ≥ 4.5 |

| Matla a phatlohang | N | ≥ 170 |

| Matla a suture a hula (5-0PET suture) | N | ≥1 |

| 303070- Lintlha tsa theknoloji | ||

| botenya | mm | 0.055-0.070 |

| boholo | mm*mm | 240×L180200×L220240×L220 240×L200 150×L150 150×L180 |

| ho kena metsing | ml/(cm2.min) | ≤200 |

| warp tensile strength | newton/mm | ≥6 |

| Weft tensile matla | newton/mm | ≥ 5.5 |

| Matla a phatlohang | N | ≥ 190 |

| Matla a suture a hula (5-0PET suture) | N | ≥1 |

| tse ding | ||

| thepa ea lik'hemik'hale | / | Latela litlhoko tsa GB/T 14233.1-2008 |

| thepa ea tlhaho | / | Latela litlhoko tsa GB/T 16886.5-2003 |

● Tsamaiso ea boleng ba ISO13485

● Kamore e hloekileng ea Sehlopha sa 10 000

● E na le lisebelisoa tse tsoetseng pele ho netefatsa hore boleng ba sehlahisoa bo kopana le litlhoko tsa kopo ea sesebelisoa sa bongaka

Tlohela lintlha tsa hau tsa puisano:

Ngola molaetsa wa hao mona mme o re romele wona.