taƙaitawa

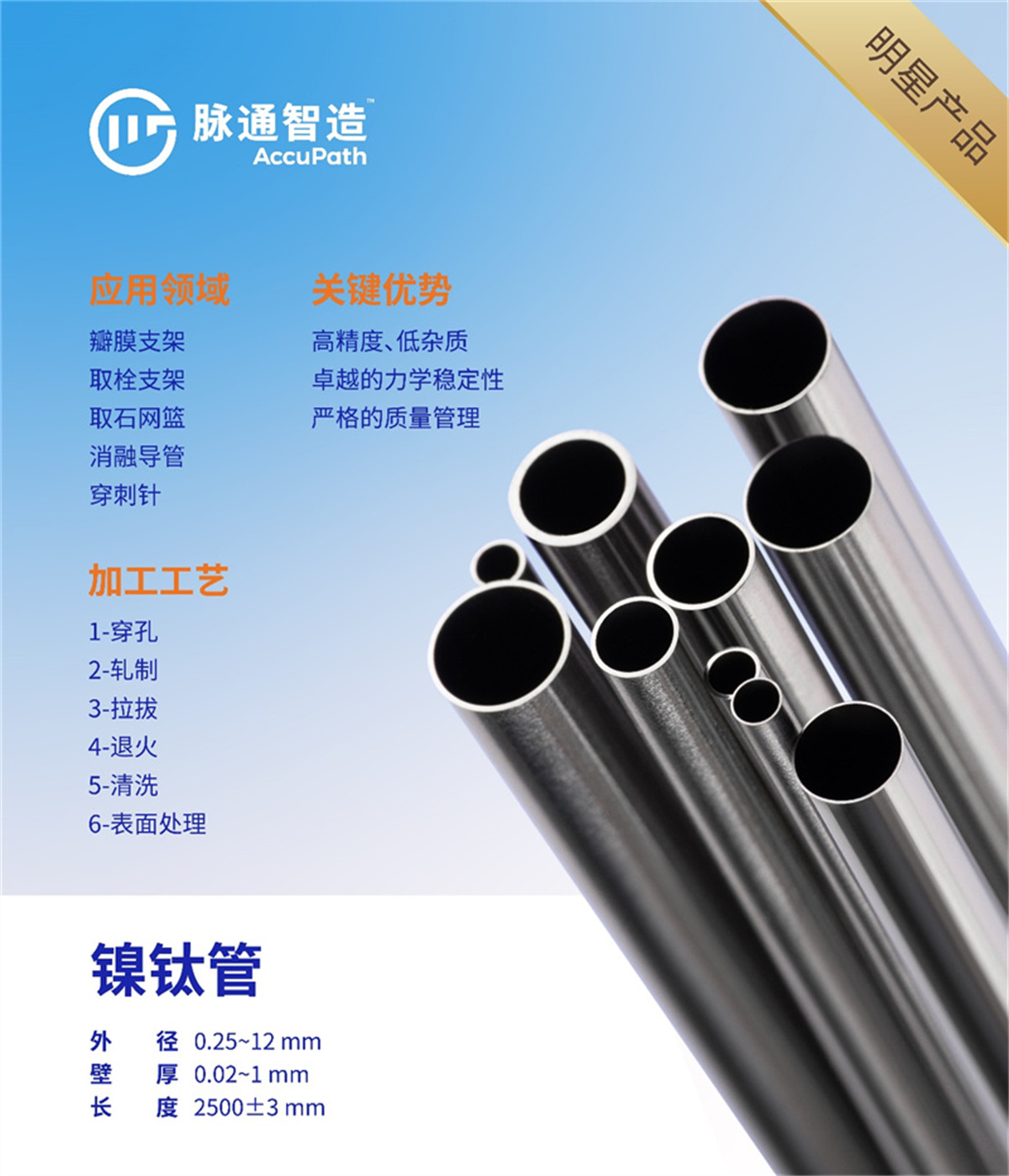

Ana ƙara amfani da bututun nickel-titanium a cikin na'urorin jiyya na shiga tsakani, kuma ƙarfinsu da yanayin ƙwaƙwalwar ajiyar su ya kawo ci gaba na juyin juya hali a fagen na'urorin likitanci. Maitong Ƙirƙirar Masana'antu™Ta hanyar fasahar yankan-baki da ingantaccen kulawa mai inganci, ana samar da bututun nickel-titanium masu girma, waɗanda ba wai kawai sun kai matakan jagorancin masana'antu ba a cikin daidaiton ma'auni da kwanciyar hankali na aiki, amma kuma suna nuna kyakkyawan sakamako a cikin tsabta da fasahar jiyya ta saman. Waɗannan sabbin samfura da sabis na keɓancewa babu shakka za su haɓaka mafi aminci mafita ga masana'antar kayan aikin likita.

Fasaha na yanke-yanke haɗe tare da kyakkyawan aikin fasaha

A cikin tsarin samar da bututun nickel-titanium, Maitong Intelligent Manufacturing ™ yana zaɓar tsarin gyare-gyaren da ya dace ta hanyar fahimtar ka'idodin canjin ƙarfe tsakanin ƙimar aikin sanyi daban-daban, jihohi daban-daban da hanyoyin sarrafawa daban-daban don tabbatar da cewa babu wani yanki da ke faruwa a lokacin bututu kwarara tsari. A cikin lalata da sarrafawa, Maitong Intelligent Manufacturing ™ yana gudanar da bincike mai zurfi game da halayen juyin halitta yayin aiwatarwa, ƙware da ƙarfin ƙarfafawa da ƙarfafa tsarin nickel-titanium gami, yana ƙara haɓaka kaddarorin inji, kuma yana samun mafi kyawun ƙarfi-plasticity. daidaitawa don biyan buƙatun na'urorin likita daban-daban.

Ƙuntataccen ingantaccen gudanarwa don ƙirƙirar ingantattun ma'auni na masana'antu

Maitong Ƙirƙirar Masana'antu™Samar da bututun nickel-titanium ya ƙunshi jerin madaidaitan matakai, daga shirye-shiryen babur bututu zuwa duba ingancin ƙarshe. Kowane mataki na sokin, mirgina, zane, annealing, tsaftacewa da kuma saman jiyya yana tare da tsananin ingancin dubawa don tabbatar da daidai sarrafa gami abun da ke ciki da kuma rage ƙazanta, don haka tabbatar da tsarkin sinadari da microstructural Properties na samfurin.

Kamfanin yana ba da kulawa sosai ga samfuran daga siyan buƙatu zuwa bita, samarwa, dubawa, da bayarwa don tabbatar da ingancin samfur. Bugu da ƙari, riƙewar samfurin a lokacin aikin samar da kayan aiki yana tabbatar da samfurin samfurin, ƙaddamar da tushe mai mahimmanci don ingantaccen bincike da ci gaba da ci gaba. Bayanan gwaji masu dacewa sun nuna:

Ƙuntataccen ingantaccen gudanarwa don ƙirƙirar ingantattun ma'auni na masana'antu

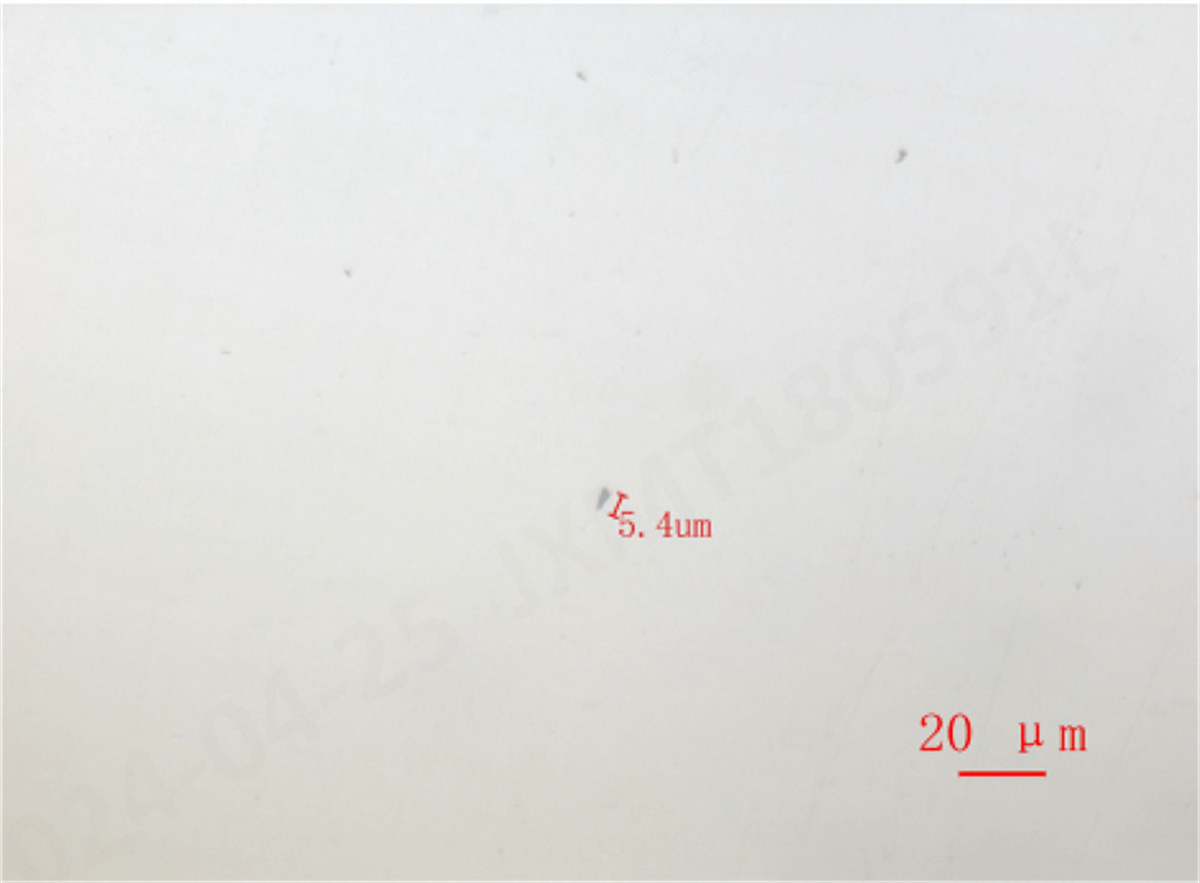

Matsakaicin girman ƙananan sassaƙaƙƙun ɓoyayyun abubuwan da ba na ƙarfe ba a cikin microstructure na albarkatun ƙasa ana sarrafa shi da kyau a cikin 5.4 μm, kuma matsakaicin yanki shine kawai 0.5%, yana tabbatar da mafi kyawun juriya ga gajiya.

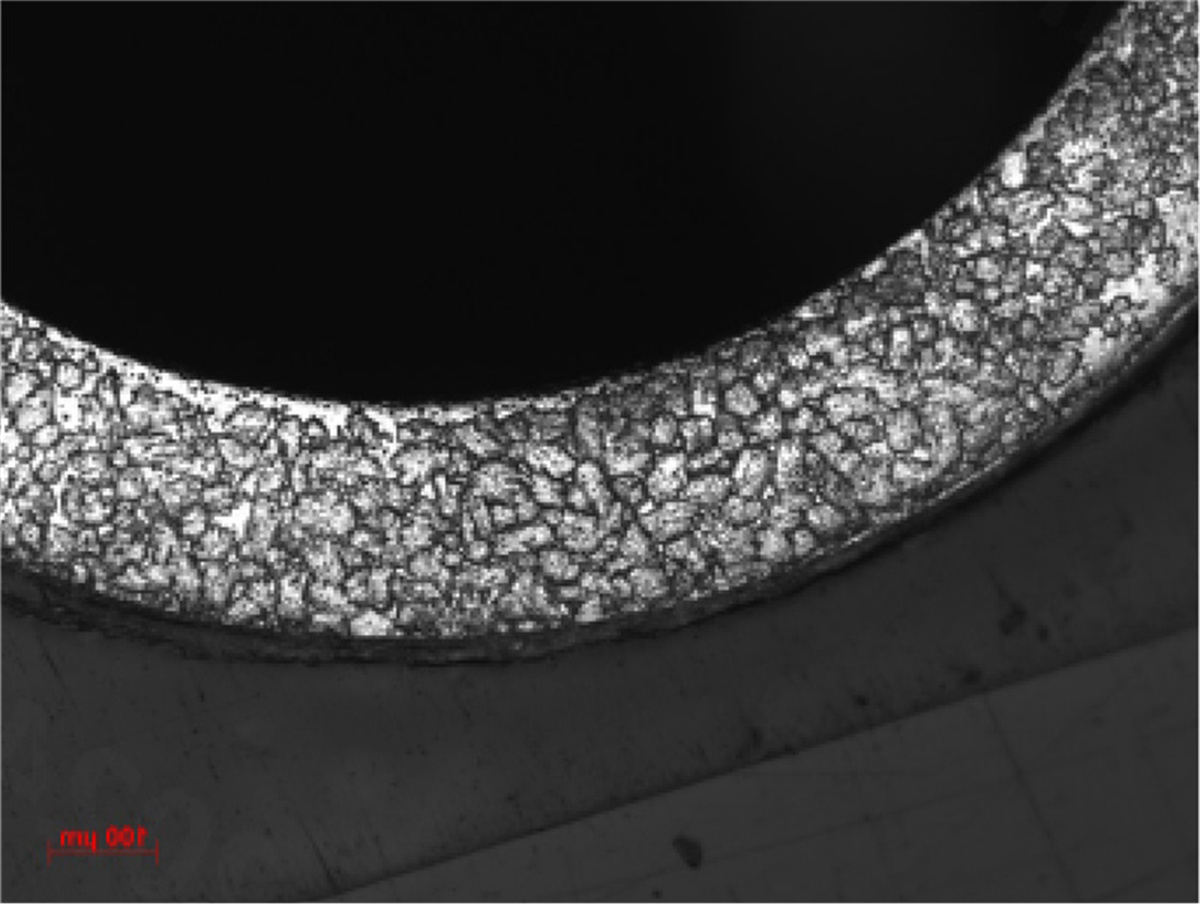

Samfurin hada da 500x

Microstructure na ƙãre bututu

Girman hatsi na bututun da aka gama ya kai matakin 7, kuma ba a sami fassarorin pores da haɗawa da abun ciki na porosity da waɗanda ba na ƙarfe ba suna da ƙasa sosai, tare da adadin yanki na 0.2% kawai, yana tabbatar da mafi kyawun juriya ga gajiya.

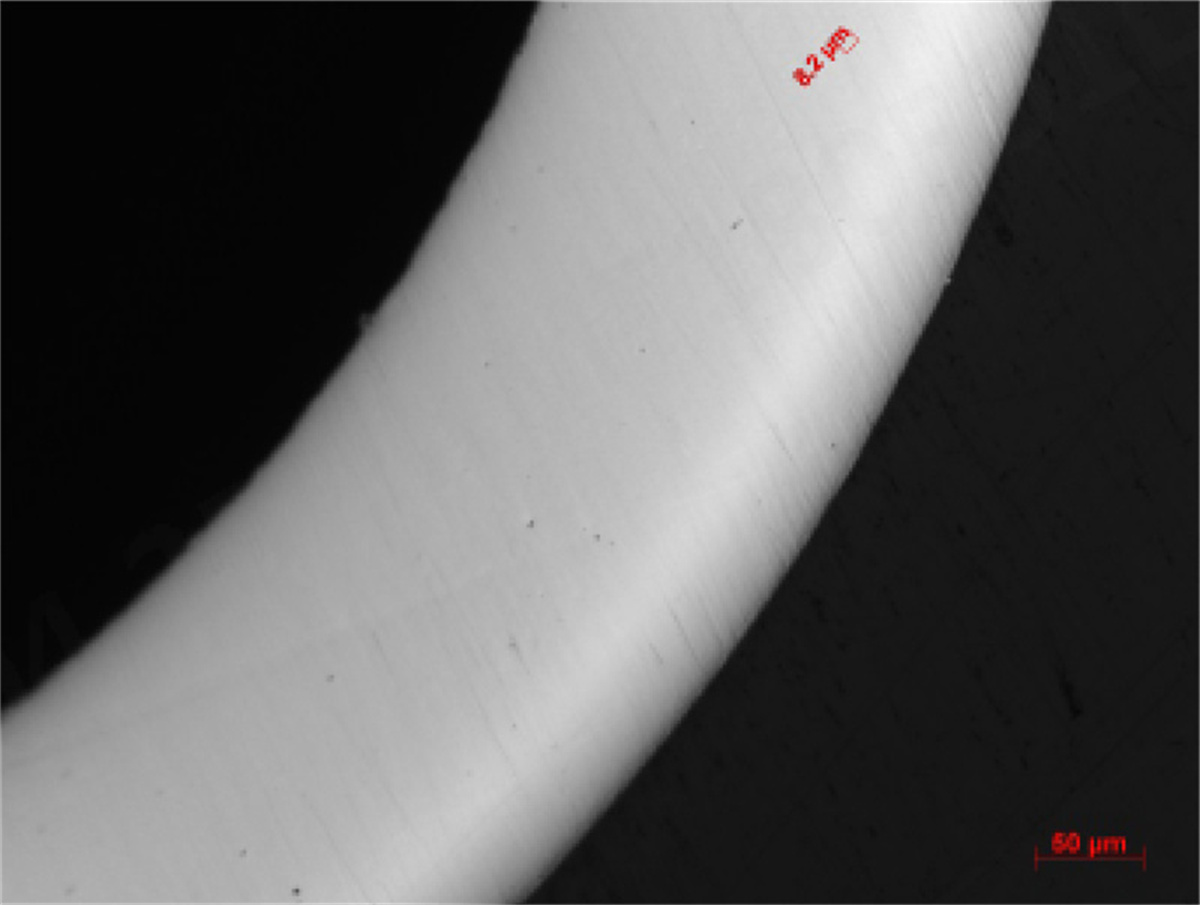

Girman hatsi na samfurin

Samfurin hada da 200x 500x

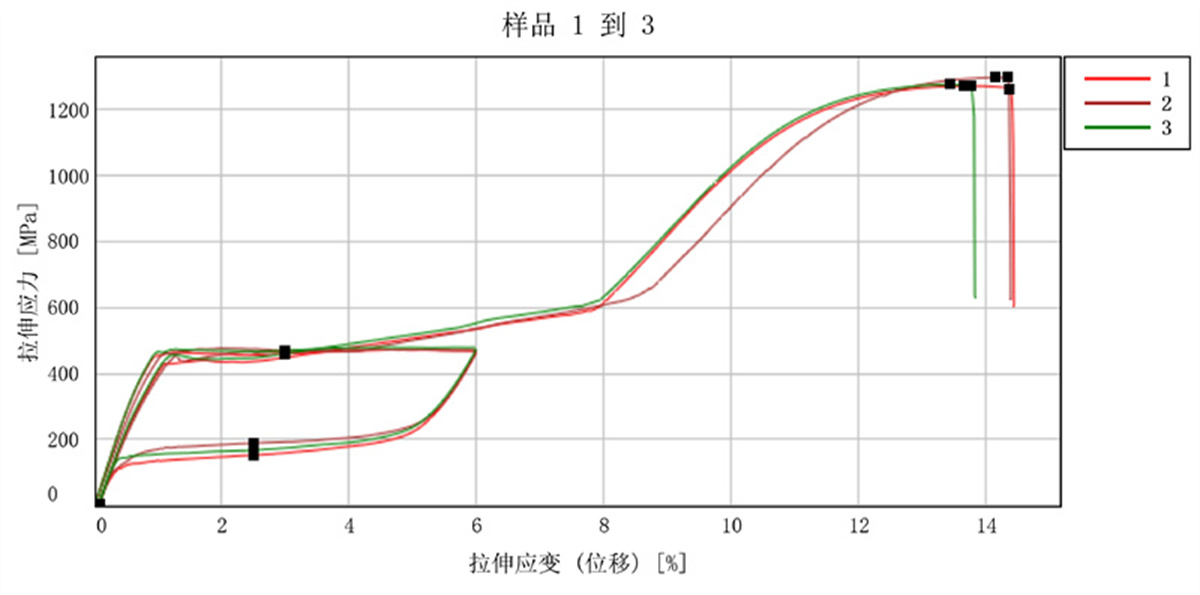

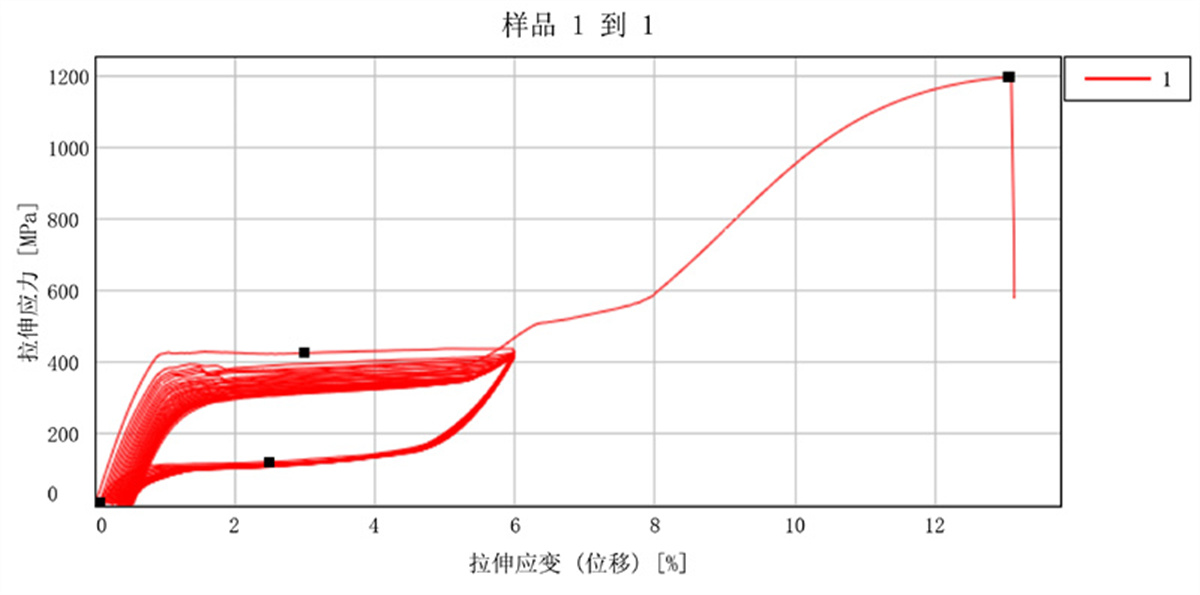

Kyakkyawan kwanciyar hankali na inji

Bayan kulawar thermomechanical a hankali da daidaitaccen yanayin canjin yanayi, samfurin ya nuna kyakkyawan kwanciyar hankali na inji bayan gwaje-gwaje 20 na 6% na sake dawo da sake zagayowar. Bugu da ƙari, samfurin yana da kyakkyawar daidaitawa kuma yana iya daidaita aikinsa bisa ga bukatun abokin ciniki.

Bugu da kari, Maitong Intelligent Manufacturing ™ yana da cikakkun kayan aikin gwaji da hanyoyin, waɗanda zasu iya gudanar da cikakken gwajin aikin tensile, nazarin haɓakar zafi, ƙayyadaddun halayen ƙwaƙwalwar ajiya, haɓakar gajiya da karaya taurin halayen samfuran.

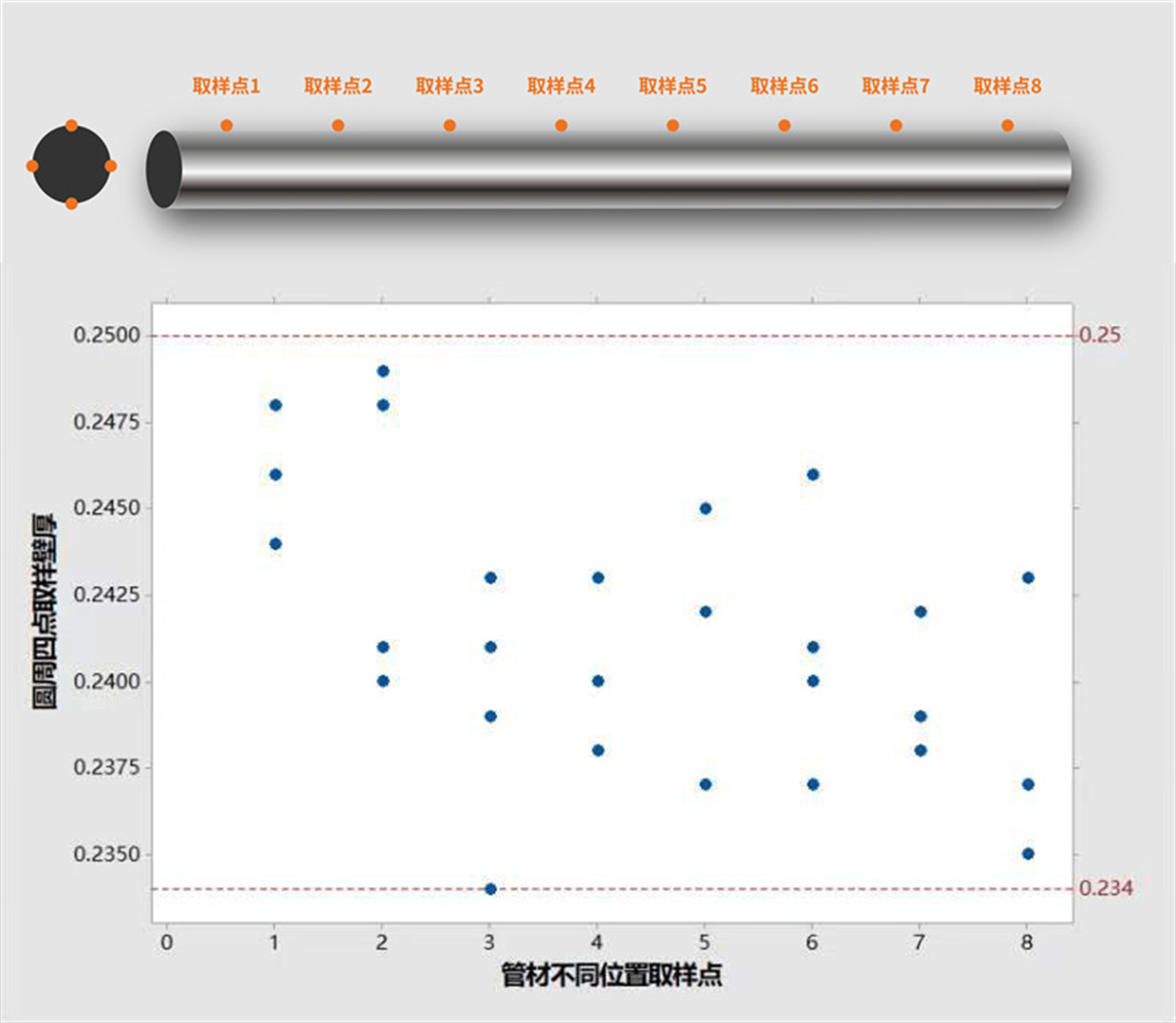

Babban madaidaici, ƙarancin ƙazanta” bututun nickel-titanium mai tsafta mai tsafta

Tare da ingantaccen tsarin gudanarwa mai inganci, Maitong Intelligent Manufacturing ™ ya haɓaka jerin sabbin samfuran bututun nickel-titanium mai tsafta tare da "madaidaicin daidaici da ƙazanta". Ta hanyar halayen gwaji, matsakaicin girman ƙazanta a cikin samfurin shine ≤12.0μm, kuma rabon yanki shine ≤0.5% Yin amfani da madaidaicin extrusion ko tsarin zane, ana iya sarrafa kauri na bangon 360 na samfurin a cikin 0.01mm.

A lokaci guda, tare da taimakon jerin ingantattun fasahohin gyare-gyaren sararin sama kamar magnetic nika da niƙa mara tsakiya, ƙaƙƙarfan (ra) na Maitong Intelligent Manufacturing ™ bututun nickel-titanium ya kai ≤0.1μm, yadda ya kamata yana haɓaka juriyar lalatawar sa. da biocompatibility.

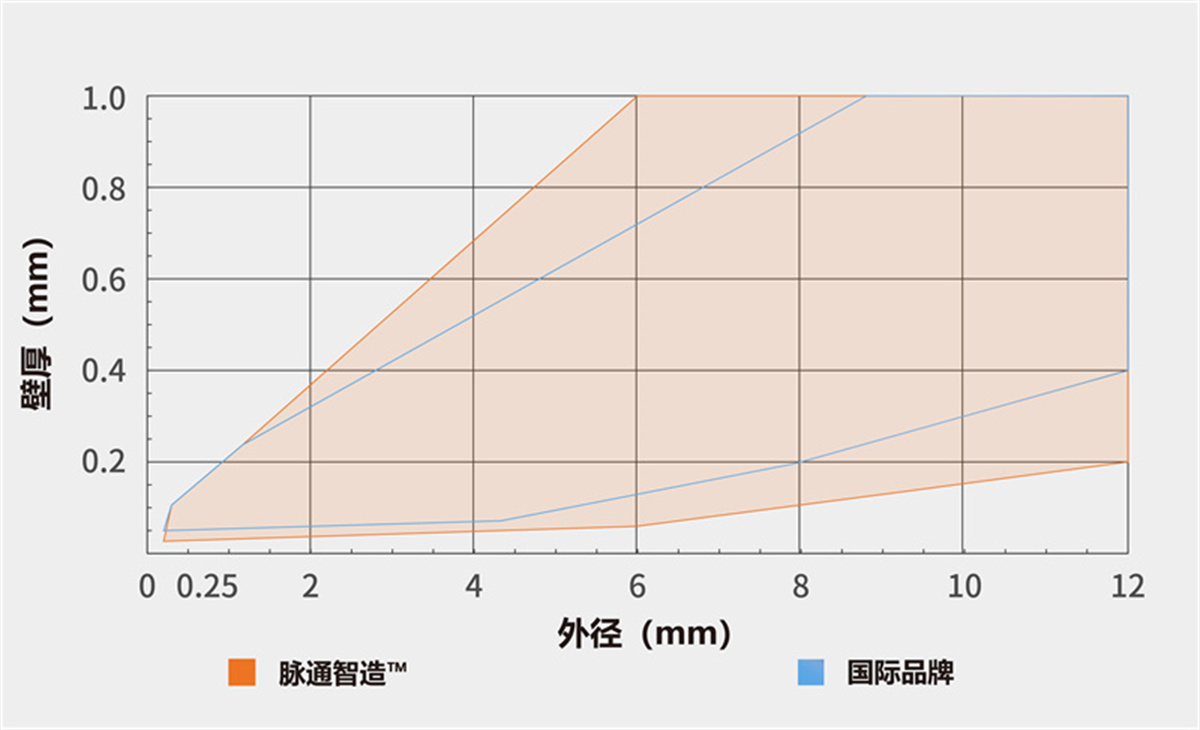

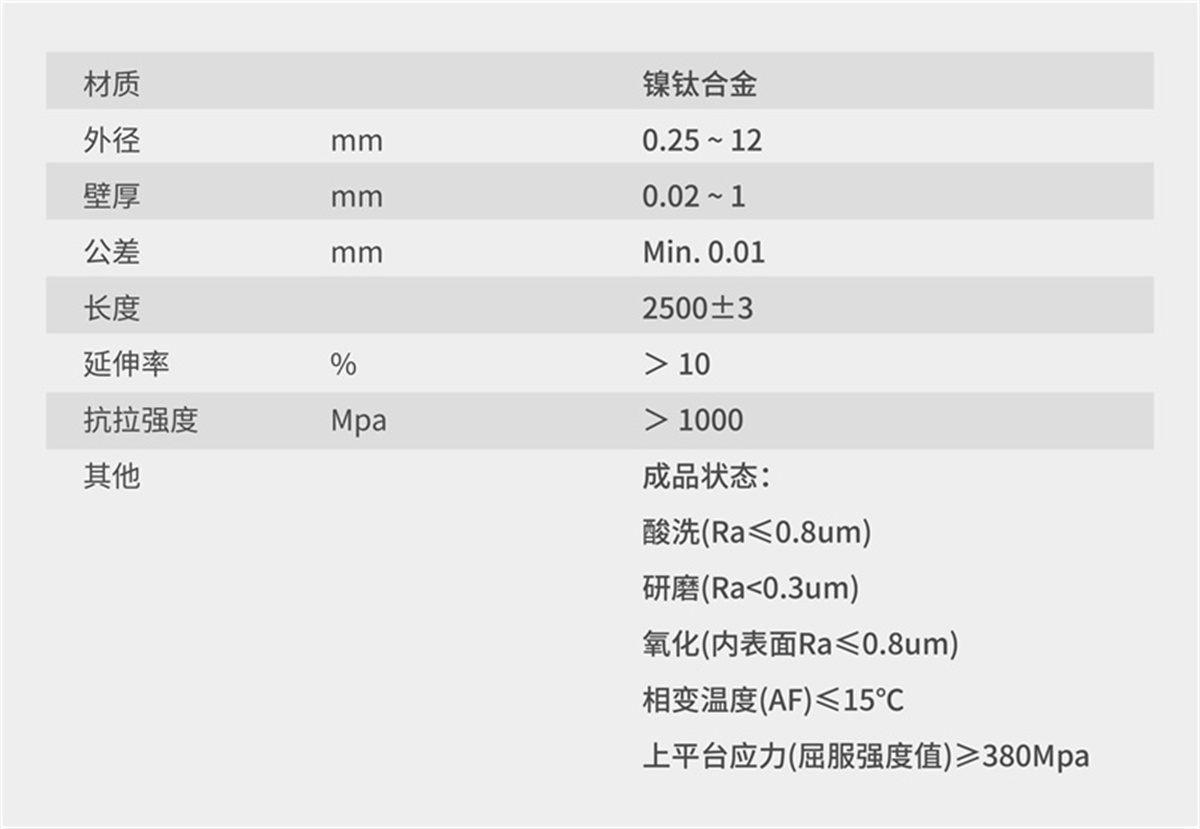

Akwai masu girma dabam

Tare da ingantaccen tsarin gudanarwa mai inganci, Maitong Intelligent Manufacturing ™ ya haɓaka jerin sabbin samfuran bututun nickel-titanium mai tsafta tare da "madaidaicin daidaici da ƙazanta". Ta hanyar halayen gwaji, matsakaicin girman ƙazanta a cikin samfurin shine ≤12.0μm, kuma rabon yanki shine ≤0.5% Yin amfani da madaidaicin extrusion ko tsarin zane, ana iya sarrafa kauri na bangon 360 na samfurin a cikin 0.01mm.

Bugu da kari, Maitong Intelligent Manufacturing™ kuma zai iya samar da musamman nickel-titanium bangaren sarrafa ayyuka bisa ga abokin ciniki bukatun, ciki har da: Laser yankan, zafi saitin, nickel-titanium bangaren polishing, da dai sauransu.

- Laser walda:Mafi ƙarancin diamita na iya kaiwa 0.003"

- Yanke Laser:Mafi ƙarancin yankan tsaga nisa shine 0.001" & matsakaicin maimaitawa shine ± 0.0001"

- Electrochemical polishing:Tashin hankali (ra) ≤0.1μm

Lokacin fitarwa: 24-05-29